| Sign In | Join Free | My udpf.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My udpf.com |

|

Brand Name : Gofun

Model Number : GFM-TPL

Certification : ISO, CE certification

Place of Origin : Shanghai

MOQ : 1 SET

Price : Negotiable

Payment Terms : T/T, L/C, Western Union

Supply Ability : 20 sets per year

Delivery Time : 90 days

Packaging Details : International standard package for shipping

Capacity : Customized

Application : tomato

Feature : High Efficiency,cheaper cost

Usage : garlic paste production line

Product name : tomato paste processing line

Power(w) : per the capacity

Voltage : 220V/380V

Warranty : 1 Year

Condition : New

After-sales service provided : Engineers available to service machinery overseas

Advanced Manufacturing Technology 304SUS Tomato Production Line 100T/D

Product description of tomato processing plant

Tomato processing lines are capable of transforming fresh tomatoes into a wide range of end products. Among the popular products are tomato paste, ketchup, and tomato juice. The tomato processing line follows a comprehensive process, starting from fresh tomatoes and culminating in the production of aseptic bagged barrels.

The process begins with the reception of fresh tomatoes, followed by washing and sorting to ensure the highest quality. The tomatoes then undergo various stages, including crushing, refining, and concentration, to obtain the desired consistency and flavor.

The processing line mainly includes: fresh tomato receiving system, washing system, sorting system, crushing system, pulping and refining system, filtration system, concentrating system, sterilizing system, and aseptic filling system. Then we can obtain tomato sauce filled in a sterile bag in the roller drum.

Barrel-packed aseptic bag ketchup can be further produced into ketchup, sauce, fruit juice, and can be filled into sachets, stand-up pouches, metal cans, PP containers, bottles, gable tops, etc.

Gofun can not only provide the tomato processing equipment for the plant but also provide the one-stop solution from A to Z, which includes:

Main parameters of tomato production line

| Product name: | One-stop solution for tomato processing line |

| Fresh fruit input capacity: | 500kg per hour ~ 25 tons per hour |

| Raw material: | Fresh tomato, tomato paste |

| End product: | Tomato paste, tomato sauce or ketchup, tomato juice, etc |

| Final product Brix: | 28%~30%, 36%~38% |

| Final package: | Aseptic bag, Metal can, Sachet, Stand-up pouch, PP container, Plastic bottle, Glass jar, etc |

| The main material for machines: | Food grade SUS304 or SUS316 |

| Warranty: | 12 months after commissioning |

| Operator needed: | About 10~12 persons |

| Voltage: | 380V 50Hz/ 110V 60Hz/ 415V 50Hz |

| (adjustable to client's country standard) | |

| Advantages: | Energy-saving, high efficiency, water-saving |

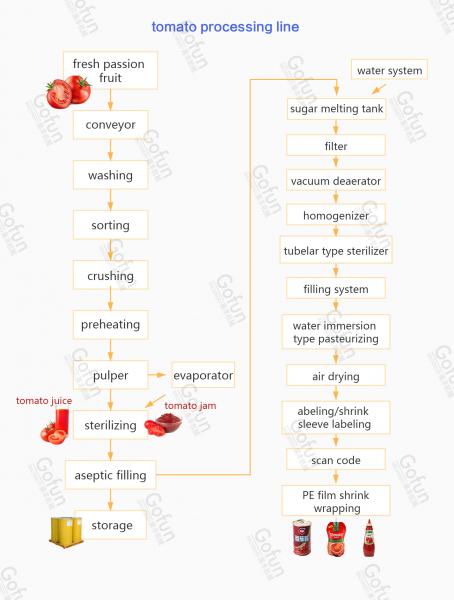

Flowchart of tomato paste/ sauce or ketchup processing

FRESH TOMATO ⇒ CONVEYOR ⇒ WASHING ⇒ SORTING ⇒ CRUSHING ⇒ PREHEATING ⇒ PULPER & REFINER ⇒ EVAPORATING ⇒ STERILIZING ⇒ ASEPTIC FILLING ⇒ STORAGE OR BLENDING

Final products & Package types for tomato project

Shanghai Gofun machinery company offers all kinds of the tomato processing line.

The raw material can be fresh tomato, tomato paste, etc. And the final product can be tomato paste, tomato ketchup, tomato sauce, tomato juice, tomato powder, whole peeled tomato, etc.

The final packaging includes aseptic bags, metal cans, sachets, stand-up pouches, PP containers, glass bottles, PET bottles, gable tops, etc.

After-Sales Service

1.debugging equipment

2.Oversea technical support

3.Oversea equipment maintenance

4.English speaking engineers available to provide technical support

Our Services for tomato processing plant

1. Technical support

2. Marketing suggestion

3. Final packing suggestion and design

4. Factory building and design

|

|

Food Grade SUS304 Tomato Production Line Customized 100T/D Images |